Manufacturing

A Steel Pipe and Tube Factory Armed with Extensive Steel Insights and Advanced Pipe and Tube Manufacturing Technology

We manufacture steel pipes at our own plants for all kinds of applications and facilities, including water supply, sewage, agricultural and industrial water and water for electric power. With product inspections based on strict in- house standards as well as JIS, JWWA, and other standards, we are capable of meeting demand for large-scale plants both in Japan and overseas. In addition, we will continue to tackle new fields, such as circulating water pipes for thermal power plants, penstock for hydroelectric power plants, and small-scale hydroelectric power generation systems using agricultural water and water supply and sewage, by utilizing our expertise in pipe manufacturing technologies such as water pipeline bridges and deformed pipes, and in manufacturing water treatment machinery, aiming to manufacture products with a view to fields other than water transportation.

FUSO Steel Pipe Plant

At the FUSO Steel Pipe Plant in Takamatsu City, Kagawa Prefecture, we manufacture steel pipes for all kinds of applications and facilities in an integrated manner.

Sophisticated Steel Insights and Technological Capabilities

Utilizing our expertise in pipe manufacturing technology and water treatment machinery manufacturing, we continue to take on challenges in various fields, including circulating water pipes for thermal power plants, penstock for hydroelectric power plants, and small-scale hydroelectric power generation systems using agricultural water and water supply and sewage.

To meet diverse needs, we provide products based on the concepts of hand-crafting and quality control using our cutting-edge technical sense and outstanding skills.

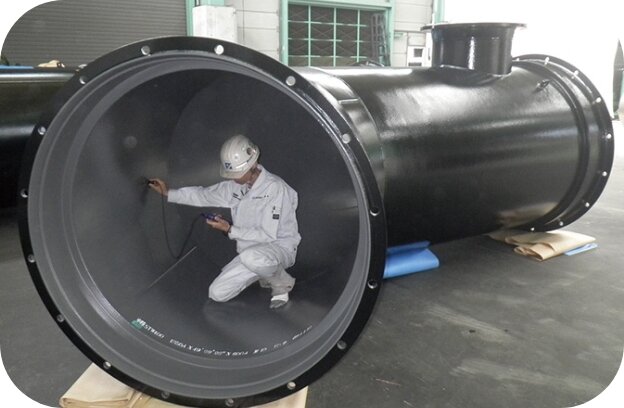

Manufacturing Processes with Integrated Quality Control

All manufacturing processes, from steel sheet cutting to coating, are performed at our own plants, where products are manufactured under a integrated quality control system that implements rigorous product inspections at each process step.

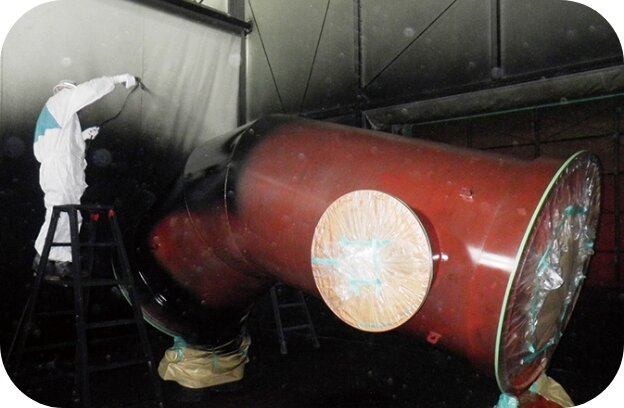

Our coating plants feature air supply and exhaust systems that can fully exchange air in the plants four times per hour and air conditioning systems that maintain optimum temperature and humidity.

See products manufactured by FUSO

Introduction Video: FUSO Steel Pipe Plant

Factory Manufacturing Line

Steel pipe plant

Coating plant

Plant Overview

| Location | 796-1, Goto Town, Takamatsu City, Kagawa Prefecture |

|---|---|

| Site Area | 56,287㎡ |

| Plant Floor Space | Pipe manufacturing plant: 10,434m2 / Coating plant: 6,770m2 |

| Pipe manufacturing capacity | Maximum diameter Φ5,000mm |

Capable of Marine Transportation

Located in a port district, the plant can ship large-diameter products by sea, which is difficult to do by land transportation. These photo show a thermal power plant circulating water pipe with a diameter of Φ4,250 mm as it leaves port.

Manufacturing Plant

The production of steel plate deformed pipes requires advanced pipe-making techniques, removal of distortion caused by various factors, and strict adherence to specified dimensional tolerances. Therefore, careful control is required in manufacturing.

FUSO's products are produced with consistent quality (management system) in terms of welding, distortion, machining, dimensions, etc., with materials that have been developed to full size that are checked in various ways at each production process. We also offer various types of coatings and covers to meet customer requirements, striving to create reliable products.

See potential applications for steel pipe manufacturing

Manufacturing Processes

1. Cutting

2. Pressing

3. Rolling

4. Automatic welding

5. Pipe cutting

6. Beveling

7. Machining

8. Assembly

9. Welding

10. X-ray inspection

11. Surface treatment

12. Interior coating

13. Exterior coating

14. Coating inspection

15. Completion

Manufactured Products

Our in-house manufacturing is focused on handcrafted excellence by artisans and covers all processes for producing steel pipes for all kinds of applications and facilities, including water supply, sewage, agricultural and industrial water and water for electric power.

See products manufactured by FUSO

Related Solutions

Pipeline Engineering and Construction

FUSO has been consistently involved in the pipeline business from the postwar reconstruction period to the present day, as we continue to respond to the changing needs of the times. As Japan's only general water infrastructure company specializing in both pipelines and facilities, we connect safe and secure water infrastructure to the community and to a better future.

Diagnosing Deterioration of Water Environments Using Drones and AI

Water pipeline bridges make it challenging to conduct inspections due to structure and other characteristics. Even under these conditions, the high-performance drone used for this service can capture clear images, which are analyzed by AI to diagnose and identify elements such as dirt and rust.

- TOP

- Our Business

- Manufacturing