Streamlining O&M through Utilization of Digital Technologies

Eliminating Skill Requirements Facilitates Easier Operation, Management, and Maintenance

FUSO's O&M (operation and management) business harnesses the knowledge and technology it has cultivated over many years of constructing water supply and sewage facilities. We solve the problems that many water infrastructure facilities face, such as deterioration and loss of engineers. We also utilize digital technologies to create systems allowing anyone to manage operations safely, securely, stably, and efficiently, keeping facilities in optimal condition.

- FUSO's Strengths

- One-stop Service Provision

- Operation, Maintenance, and Management Services at the Kagawa Water Supply Authority

- Robot Cleaning of Water Distribution Reservoirs

- Water Supply Pipeline Leakage Information Management System (AIMS)

- Cloud Monitoring System (FIC'S)

- Camera Surveys Inside Water Supply Pipes

- Diagnosing Deterioration of Water Pipeline Bridges Using Drones and AI

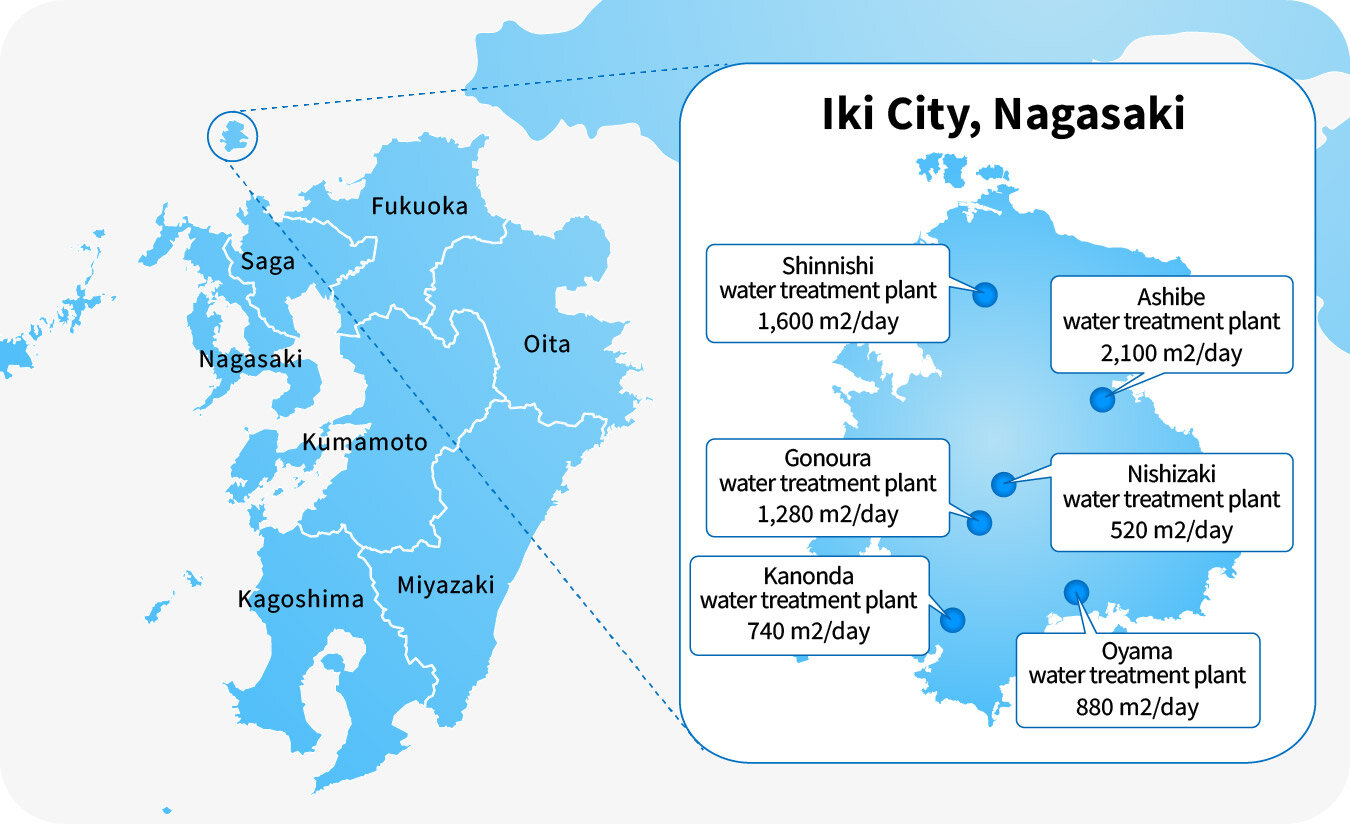

- Operation Monitoring and Maintenance Inspection of Water Supply Facilities in Iki City, Nagasaki Prefecture

- FUSO Promotes Digital Transformation

FUSO's Strengths

Extensive Expertise and Insights

At FUSO, we are committed to solving O&M issues with the knowledge and field capabilities cultivated in the water infrastructure domain for more than 70 years since our founding.

One-stop Solutions

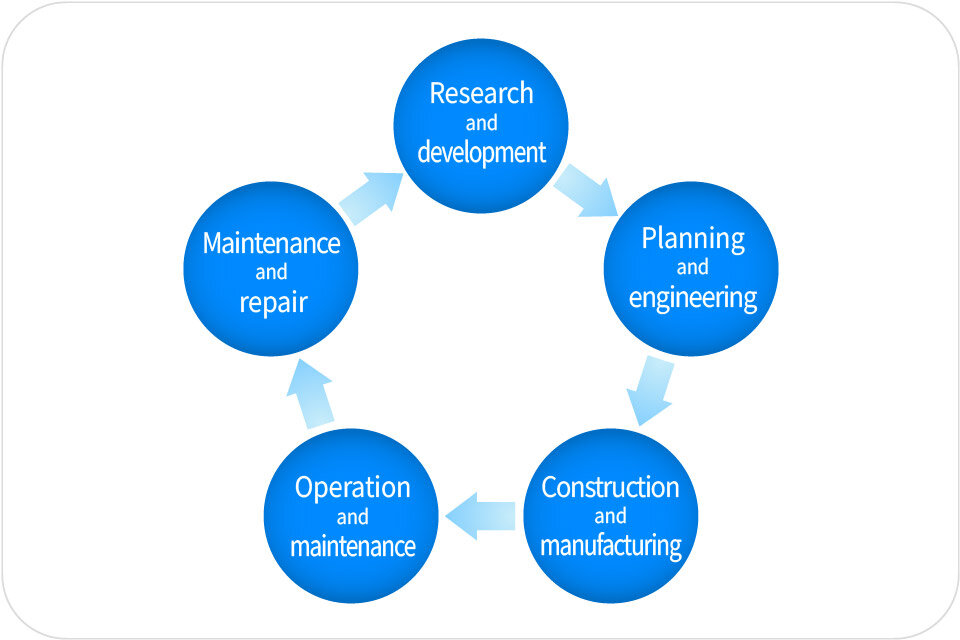

Not only do we handle all processes from facility engineering to construction, but we also provide one-stop services for facility operation and management after construction.

Eliminating Skill Requirements

FUSO's goals for DX (digital transformation) are to make it easy for anyone to handle tasks and to improve efficiency. Resolving manpower and technology challenges.

One-stop Service Provision

We are able to handle the engineering, procurement, construction, operation management, and maintenance of water infrastructure in one stop, and can flexibly plan, propose, and implement solutions to the unique issues of each region. Because we are skilled in all processes, we can provide high-quality services through synergy.

Operation, Maintenance, and Management Services at the Kagawa Water Supply Authority

In December 2022, a contract was signed with a joint venture (as one of four constituent companies) as a private partner for operation and maintenance of water purification facilities and other services in Kagawa Prefecture. Operation and maintenance services are currently underway in the Chuusan and Seisan areas, which cover approximately half of Kagawa Prefecture. In this project, under the theme of "connecting," we are striving to standardize the quality of work and strengthen information sharing.

In addition to normalizing the operation and management level, we offer annual repair and improvement proposals to normalize facility functions.

1) Normalizing quality of work

In addition to normalizing the level of operation and management services, we propose annual repair and improvement proposals to normalize facility functions.

2) Strengthening information Sharing

Utilizing cloud servers and tablets, facility information (reports, ledgers, emergency material stockpiles, etc.) is shared among all parties involved. With our roots in Kagawa Prefecture, we also aim to efficiently manage facilities and improve service quality to achieve the goals of our hometown partner, the Kagawa Water Supply Authority.

About the Kagawa Water Supply Authority

Kagawa Prefecture is the smallest of Japan's 47 prefectures, with 0.5% of the national land area, and approximately 920,000 residents live in this prefecture where land use has achieved a high level of evolution. In recent years, water supply utilities have experienced dramatic environmental changes, leading to an urgent need to address issues such as a decrease in the population receiving water due to population decline, increased demand for renewal due to deteriorating facilities, earthquake resistance in anticipation of a potential Tonankai earthquake or Nankai Trough earthquake, deterioration of technical capabilities due to staff retirement, and preparation for frequent droughts.

In Kagawa Prefecture, in an effort to drastically review water supply management, the prefecture and eight cities and eight towns under its jurisdiction joined forces in November 2017 to establish the Kagawa Water Supply Authority, which began operations in 2018. In fiscal 2028, the authority aims to terminate its legacy separated accounting system and achieve uniformity in water rates.

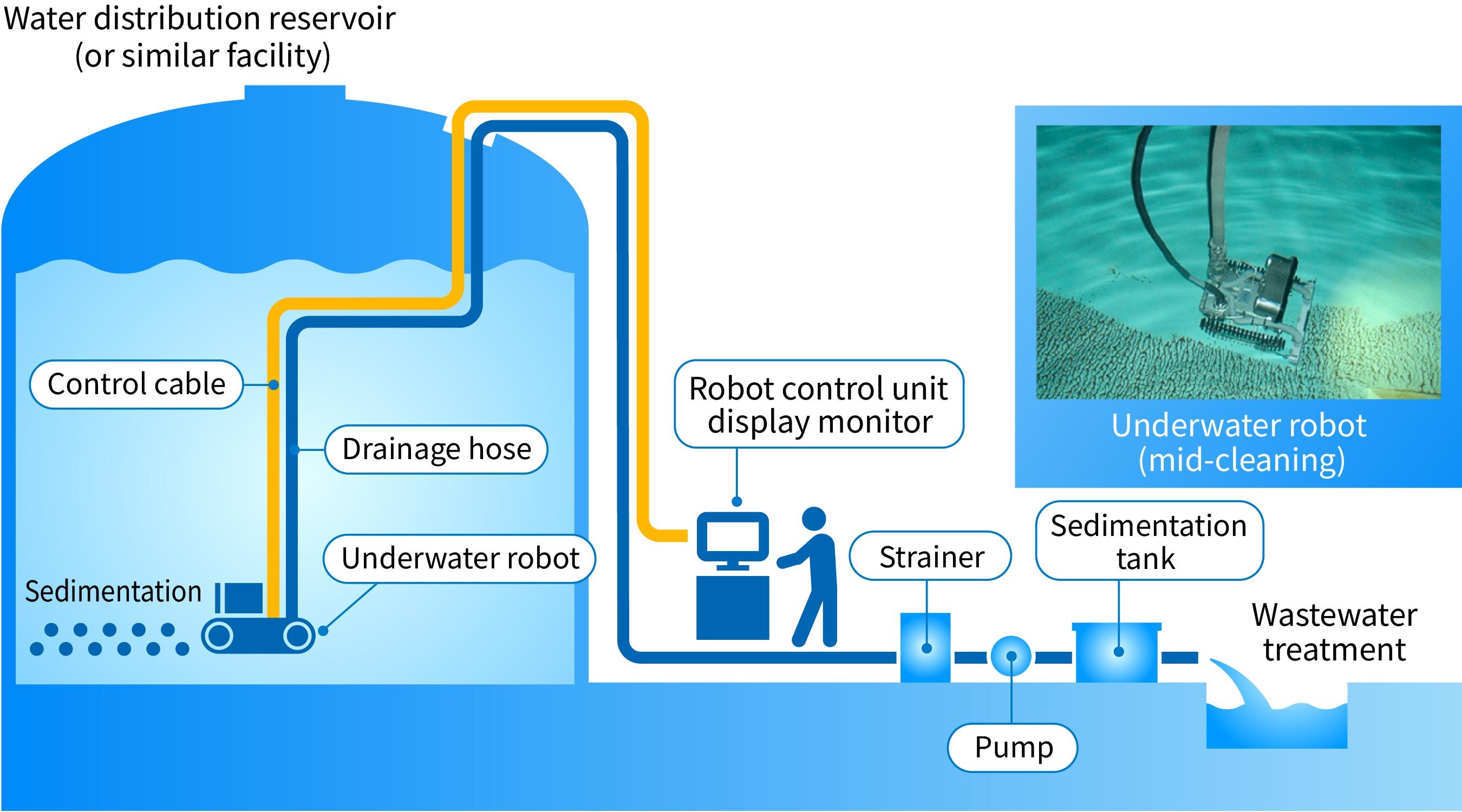

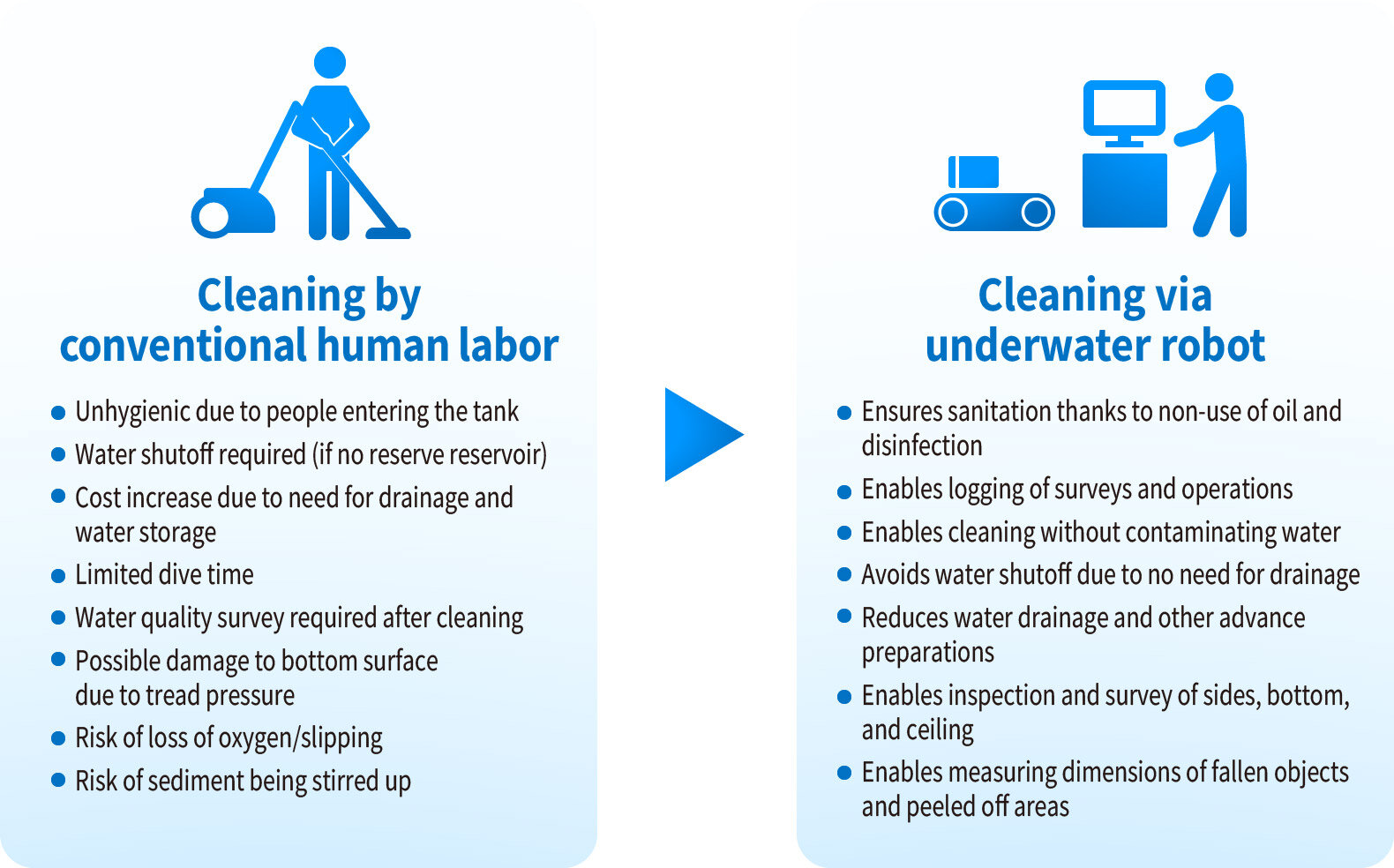

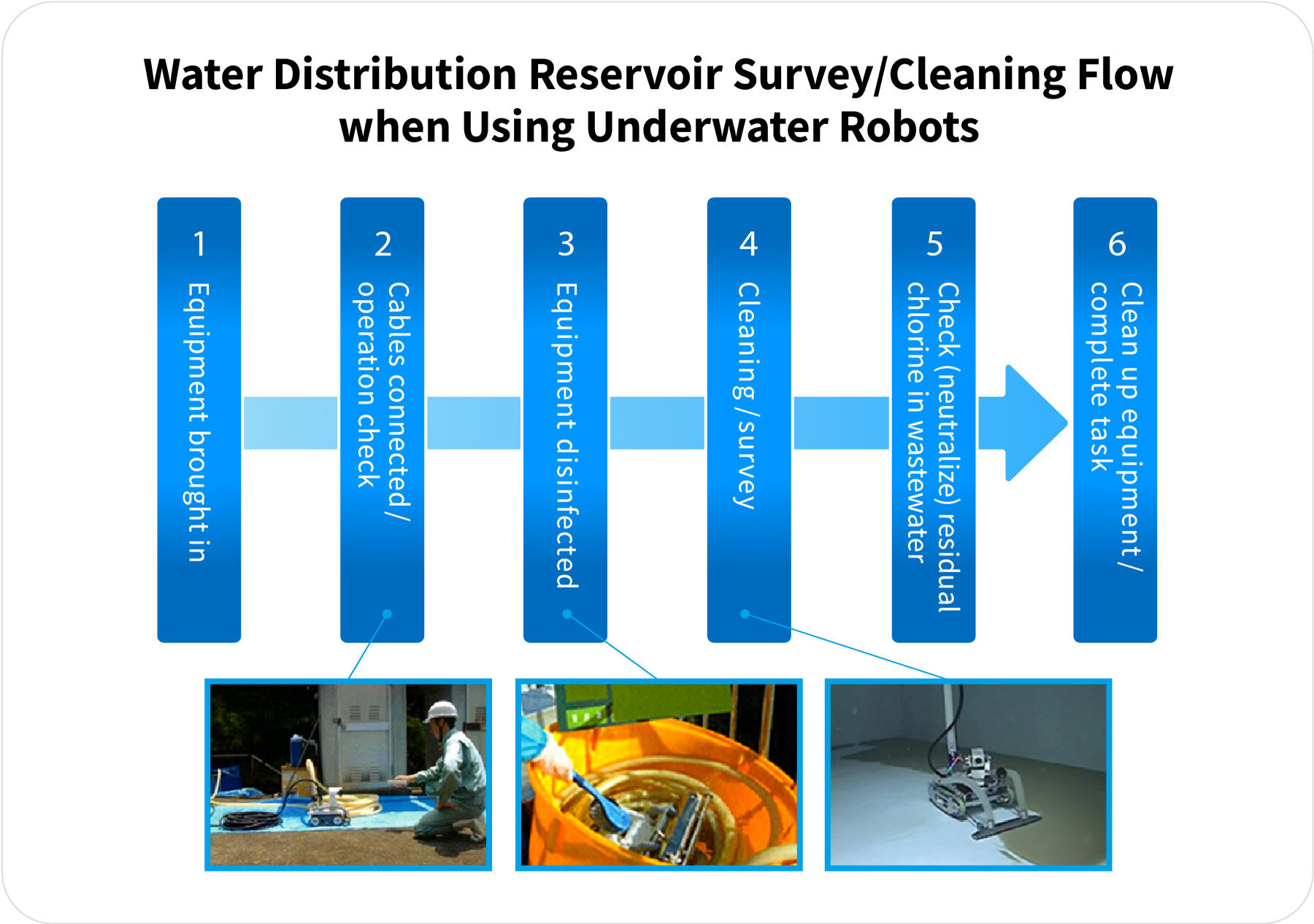

Robot Cleaning of Water Distribution Reservoirs

Water distribution reservoirs store water used for water supply, provide stable water distribution according to demand, and can also serve as emergency water supply centers in times of emergency. Even in situations where downtime is not acceptable, underwater robots can safely and hygienically survey and clean to enhance the stability of the water distribution system.

Achieving Both High-precision Internal Surveys and Safe Cleaning Operations

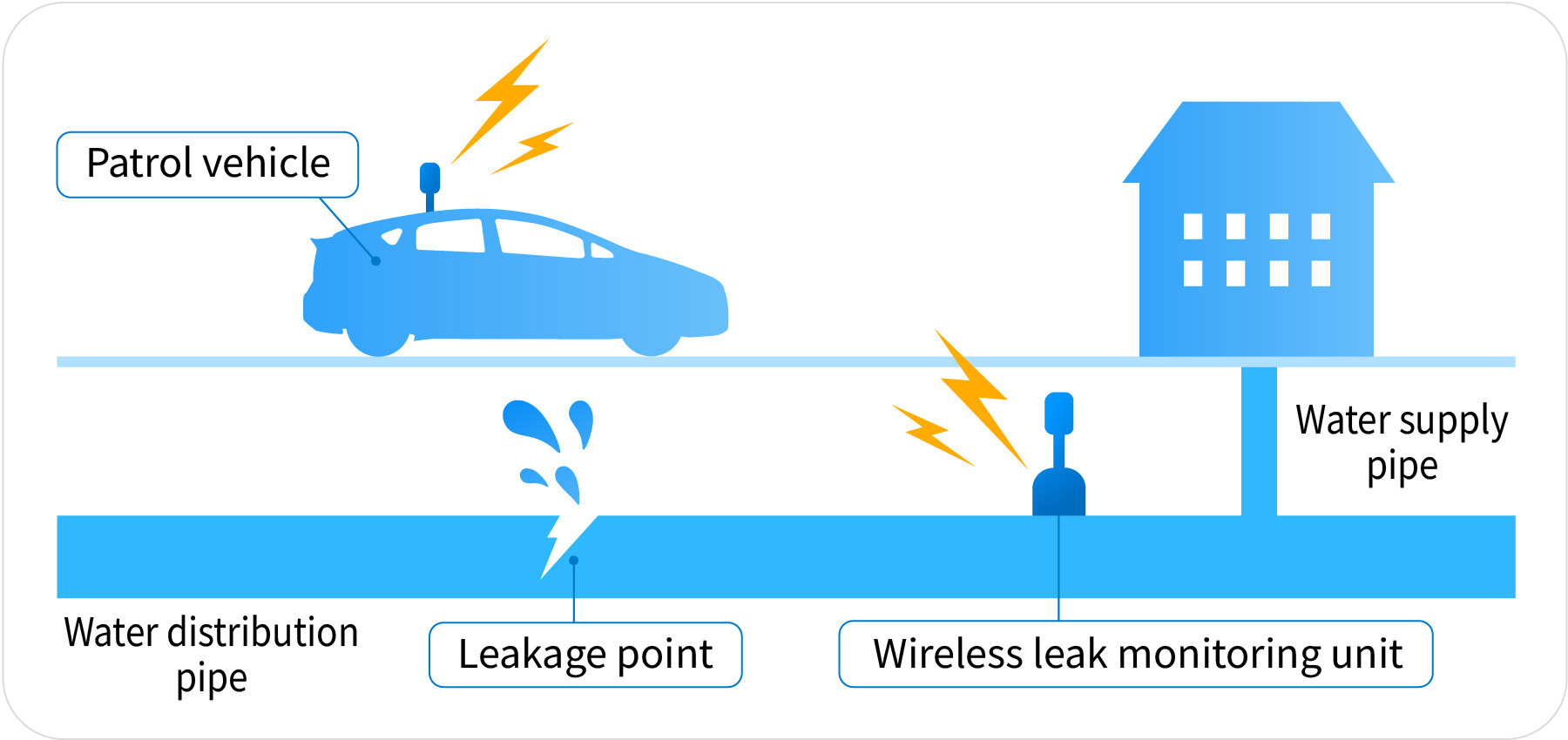

Water Supply Pipeline Leakage Information Management System (AIMS)

Leaks in pipelines not only increase the amount of water needing to be purified and increase environmental impact, but also cause secondary disasters and impact on people's lives due to water outages. FUSO contributes to the establishment of sustainable water supply systems by automatically, accurately, and efficiently detecting leaks in distribution pipes with its next-generation water pipeline leakage information management system (AIMS), which uses wireless leak monitoring units.

Problems with Conventional Leakage Surveys (Sound Level Surveys)

Sound surveys by human surveyors pose the dilemma that they are susceptible to weather and traffic conditions, and that water utilities are also unable to verify the results of leakage surveys. Another aspect is that surveys are often conducted at night when there is little traffic, which places a heavy burden on the surveyor.

Utilizing AIMS for Leakage Surveys

AIMS is a system in which wireless leak monitoring units are permanently installed over a wide area of water pipeline facilities and vehicle patrols are conducted periodically to spot investigate areas where leakage has been identified. AIMS not only solves the challenges of traditional survey methods, but also finds leaks efficiently and accurately.

AIMS' Strength #1

Transmitters equipped with high-sensitivity vibration sensors are fixed to partition valves and other areas of pipelines to transmit leakage information.

AIMS' Strength #2

Leakage information is transmitted to receivers installed on patrol vehicles.

AIMS' Strength #3

Rapid leak detection and treatment is possible by transmitting leak location information to a management tablet or PC.

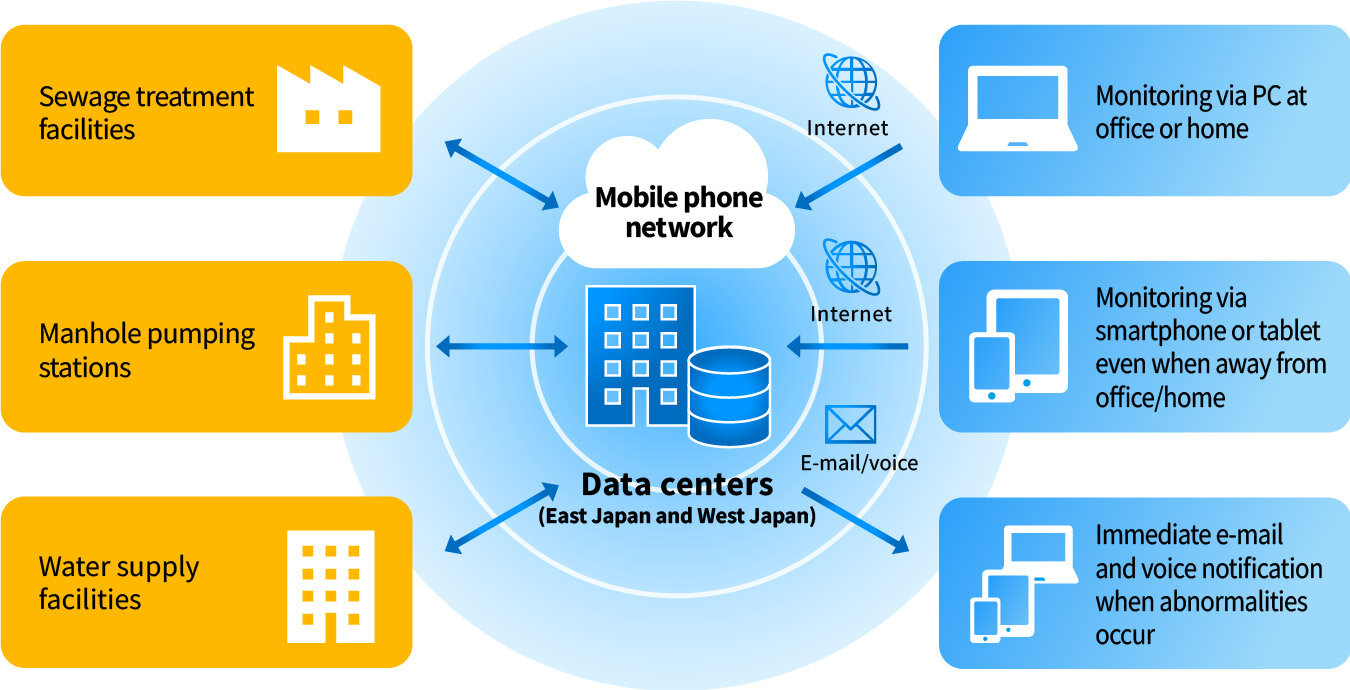

Cloud Monitoring System (FIC'S)

FUSO's cloud monitoring system, FIC'S, was introduced to solve the challenges of maintaining and managing facilities due to a declining population and deteriorating facilities. FIC'S enables central management of remote monitoring information for various facilities such as water treatment plants, sewage treatment plants, and pumping stations. In addition, storing data in the cloud not only enables access from outside the office, including while outdoors and otherwise in the field, but also helps with business continuity planning (BCP) in the event of a disaster.

Example Installation at a Water Supply Facility

We introduced a remote monitoring system for integrated management of water supply facilities in a wide area using IoT terminals. This system monitors water level, flow rate, residual chlorine, etc., and notifies users by e-mail or voice when alert values are reached.

Example Installation Outdoors with No Traditional Power Supply

Utilizing solar power generation, we installed a monitoring system outdoors in an area with no traditional power supply. A small 30 Ah condenser allows for continuous operation for three days even without sunlight. Small IoT terminals are utilized to transmit water levels and images.

Example of Water Level Monitoring System Construction

We constructed a water level monitoring system using a battery-powered terminal and a flooding sensor. This system utilizes flooding sensors smaller than a business card, creating battery-powered IoT that fits in the palm of your hand. When the flood sensor is triggered, communication is initiated to the cloud server.

Camera Surveys Inside Water Supply Pipes

Luminous (NH-40): Non-shutoff Water Endoscopy Camera

This in-pipe camera is utilized much like a colonoscopy or endoscopy for humans. This is a kind of health checkup of water pipes that periodically diagnoses based on pipe history, etc., and uses an endoscopic camera to check sections and routes that are assumed to have problems, leading to appropriate measures such as cleaning and renewal. It enables effective use of budget and planned renewal in accordance with appropriate renewal plans.

Strengths of Cameras Inside Water Supply Pipes

(1) It is possible to capture images from the inside of the pipeline without cutting off the water supply

(2) Maximum vertical insertion distance from one point of 35 meters (up or down)

(3) Camera is inserted using a ball-type repair valve, so no construction work is required

(4) Even if there is no point for inserting the camera, it is possible to insert it via a saddle water diversion valve (50 mm diameter)

(5) Applicable pipe diameter: 75 mm to 800 mm

(6) Compatible with all pipe types except asbestos pipes

(7) Equipped with automated leveling function, recording function, insertion distance meter

Past Camera Surveys Inside Water Supply Pipes

Manganese Deposits

A thick layer of blackish brown manganese was adhered to the entire tube. This solution allows for checking cubic volume as well. This manganese was identified as the cause of turbid water.

Inner Surface Coat Peeling

Our solution confirmed that the inner surface coating had deteriorated to the point that it would peel just from the camera movement. Peeling and leakage of seal coating fragments was observed. It was confirmed that the main conduit was the likely source of the leakage of the coating fragments.

Inner Surface Coat Peeling

A stone was observed to be lodged in a lower valve portion, preventing it from being fully closed.

Valve Abnormalities

Our solution confirmed that deterioration in the soft seal valve's rubber caused a loss of ability to open and close, identified as the cause of leakage of foreign objects.

Sedimentation

A large amount of sand and pebbles were observed deposited at the bottom of the pipe.

Diagnosing Deterioration of Water Pipeline Bridges Using Drones and AI

We are developing an innovative deterioration diagnosis service technology for water pipeline bridges, which are difficult to inspect due to their structure and characteristics. The high-performance drone used for this technology can capture clear images, which are analyzed by AI to diagnose and identify elements such as dirt and rust.

Strengths

1) Capable of capturing images at any point on the water pipeline bridge

This solution is capable of inspecting the bridge from both inside and outside at all angles, even in a narrow inspection space. High-illumination LED photography from the drone's point of view allows clear images to be taken even in areas where flight with the naked eye is not possible and/or where light levels are insufficient. Inspection can also be performed at high places where scaffolding is normally required and on the tops of overhead pipes, which are difficult to visually inspect.

2) Stable flight capability

The drone can maintain stable flight even when it comes in contact with an object due to approaching too close for the purpose of image quality. The omni-directional guard allows stable flight even if the drone comes in contact with surrounding objects during flight, and enables precise photography and inspection of overhead pipes and trusses, which are difficult to inspect with general-purpose drones.

3) Low skill requirement

Once a point cloud model is created and a flight route is set, automatic flight at a constant speed and altitude is possible. Inspection targets where signals are inhibited require a drone with stable flight performance even in non-GNSS (global navigation satellite system) environments. Stable automatic flight is also possible even under automated operation conditions when moving between GNSS and non-GNSS environments.

4) High-precision diagnosis results

AI reads images of water pipeline bridges and identifies dirt, rust, etc. in a three to four-level assessment. This analysis culls large amounts of similar data to eradicate the increase in man-hours required to check captured data, which has been a matter of concern. This makes it easy to identify areas with significant deterioration and areas to be monitored, thereby reducing the amount of data storage and making it easier to conduct follow-up assessments.

5) Real-time confirmation

Data captured from the drone's viewpoint can be output to an external monitor or mirrored (image sharing) on a tablet, allowing observers other than the operator to check the data in real time. This can be used to quickly identify and record deterioration in the field.

6) Acquires rich and useful data

The standard drone loadout includes 4K/infrared cameras and LiDAR, enabling it to acquire video, still images, infrared images, and point cloud data, as well as display flight trajectories within the acquired point cloud data using flight logs.

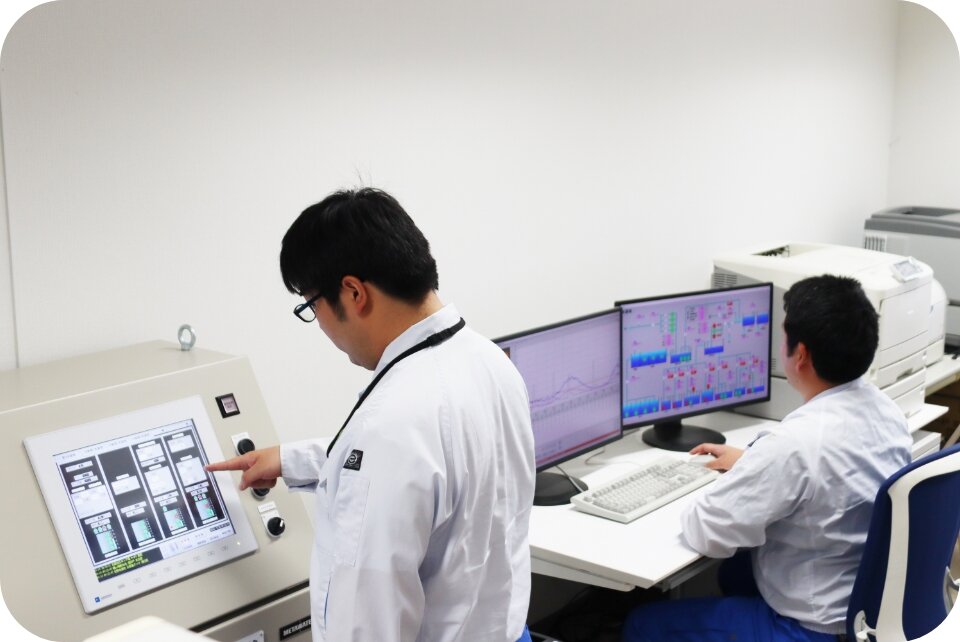

Operation Monitoring and Maintenance Inspection of Water Supply Facilities in Iki City, Nagasaki Prefecture

We are engaged in testing to revitalize technical succession harnessing information and communication technologies (ICT) through operation monitoring and maintenance inspection of water supply facilities in Iki City, Nagasaki Prefecture.

Background and Issues

Iki City as a single municipal entity was formed in 2004 with the merger of four towns across the island of Iki. The new city was host to more than 150 waterworks-related facilities in 11 areas within this large city of 134.63 square kilometers, and these facilities have been deteriorating. The operation and management of these facilities had been reliant on the skilled techniques of veteran staff who were familiar with the characteristics of each area and facility. However, the expertise accumulated through years of experience had not yet been put into a form that could be easily used to pass on to future generations, which was an issue in terms of technology succession. Another challenge was the analog nature of managing insights from inspections, daily reports, and information about facilities and equipment.

Harnessing ICT to Visualize Expertise Possessed by Veteran Staff

Establishing a scheme to enable others to efficiently acquire the expertise held by veteran staff is a challenge faced by many municipalities, but the construction of an equipment database and the computerization of methodologies have helped facilitate passing down this expertise. The system allows inspectors to use tablets in the field to input results, making it possible to keep a complete record of findings in the field. The recordings, which combine photos, videos, audio, and notes, are used as specific and easy-to-understand materials for reporting.

By building systems where users not only input location information of all facilities into the map on the system, but also where they input information on equipment at water treatment plants and input and view the history leading up to the directed actions, enables a chronological understanding of what happened and when, and how the actions were taken. Through batch conversion of information into digital data, we can create an environment in which information can be accessed whenever and wherever it is needed, freeing people from the hassle of searching for paper documents.

FUSO promotes digital transformation

Evolving Water through Transformation Rooted in Communities

FUSO will use digital technologies to solve the challenges facing water infrastructure and pursue sustainability both for water and for communities.